PES

MEMBRANE FEATURES

Excellent physical and mechanical properties:

The weight of a single membrane wire is over 500g, the blasting pressure is over 1.5 Mpa, and the unique anti-deformation ability ensures that the membrane wire is not only subjected to the fluctuation of pressure but also the impact of water flow during the operation, the membrane hole does not deform, in the precise separation, the bacteria filtration, the pyrogen interception and so on working condition, guarantees the liquid production quality the fine and the stability.

The strongest thermal stability:

The high-temperature resistant membrane module can be made by using the high-temperature resistant membrane shell and the high-temperature resistant sealing material.

Good chemical corrosion resistance:

The membrane filaments can be used under various complicated working conditions because of their good chemical corrosion resistance. When the membrane filaments are polluted, there are many cleaning methods to be chosen to restore the flux.

High hydrophilicity and low energy consumption:

The hydrophilic polymer material was used to modify the membrane filaments, so that the membrane filaments had permanent hydrophilic modification effect, and the water production was close to 0 pressure, very low transmembrane resistance, lower water production energy consumption, and lower membrane surface pollution, the frequency of cleaning is reduced, and the service life of the membrane is prolonged.

SUPPLEMENTARY INSTRUCTION

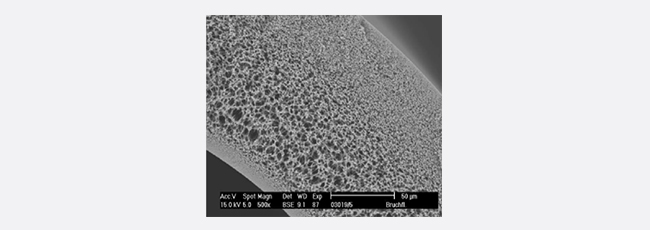

1. Double-cortex structure, double-filtration.

2. Sponge-like cubic mesh structure, high mechanical properties of membrane filaments, mesh interpenetrating each other, porosity up to more than 70% , high water-passing efficiency.

3. PES resin has passed food and drug health certification in many countries.

4. Excellent biocompatibility, can be used in hemodialysis and other industries.

5. The Thermoplastic has the best anti-creep ability, ensuring that the filaments will not be subjected to long-term stress and deformation during long-term operation, and that the holes of the membrane will not change, thus ensuring the filtration accuracy.

6. The inside and outside diameter should be ± 0.01 mm.

7. The difference between maximum wall thickness and minimum wall thickness is controlled within 0.01 mm.

8. PES-6K is specially made for pyrogen interception.

9. PES-50k strong alkali membrane is specially prepared for high concentration alkali filtration.

10.Specially made PES-100K high strength and high flux for replacement of imported products.