PVDF(enhanced)

MEMBRANE FEATURES

Excellent physical and mechanical properties:

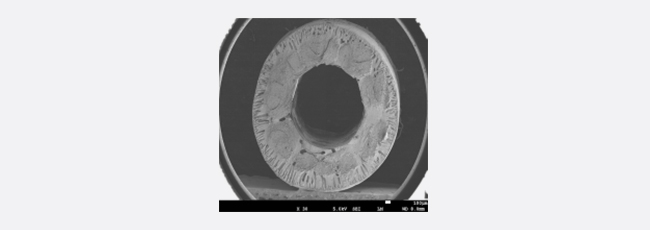

The integrated forming process of inner lining layer, (average) breaking tensile strength up to 17386CN, ensures the continuous breaking of filaments and the non-delamination of membrane filaments during the operation, and ensures the excellent effect of the system operation.

Excellent chemical corrosion resistance:

The maximum residual chlorine tolerance of membrane filaments can reach 5000 ppm, which can be widely used in various harsh water quality conditions and operating conditions requiring high concentration of oxidant, prolong the service life of the membrane.

Strong anti-pollution ability:

The polarity and surface smoothness of the membrane filaments are improved by using international high-quality raw materials, advanced membrane formulation and technology, which makes the surface of the membrane filaments not easy to adhere to pollutants, reduces concentration polarization, and enhances anti-pollution performance.

High hydrophilicity and low energy consumption:

The hydrophilic polymer material was used to blend and modify the membrane filaments, so that the membrane filaments had permanent hydrophilic modification effect, and the water production was close to 0 pressure, with very low trans-membrane resistance and lower energy consumption, and the fouling of the membrane by organic matter was reduced, the cleaning frequency is reduced, and the use is convenient and the service life is prolonged.

SUPPLEMENTARY INSTRUCTION

1. The flux of PVDF membrane filaments was higher than that of conventional PVDF membrane filaments.

2. It is not easy to break, and the breaking tension of single membrane wire is above 170N, so it will not break in practical application.

3. Anti-desquamation performance is good, through formula and spinning process optimization, leather and lining tube adhesion is stronger, not desquamation back wash.

4. Strong anti-pollution ability, strong anti-cleaning ability.